|

|

||

|

MST_K07_CL - SPEED REGULATOR FOR UNIVERSAL MOTORS WITH TORQUE CONTROL |

||

|

||

|

1 >>>

|

||

|

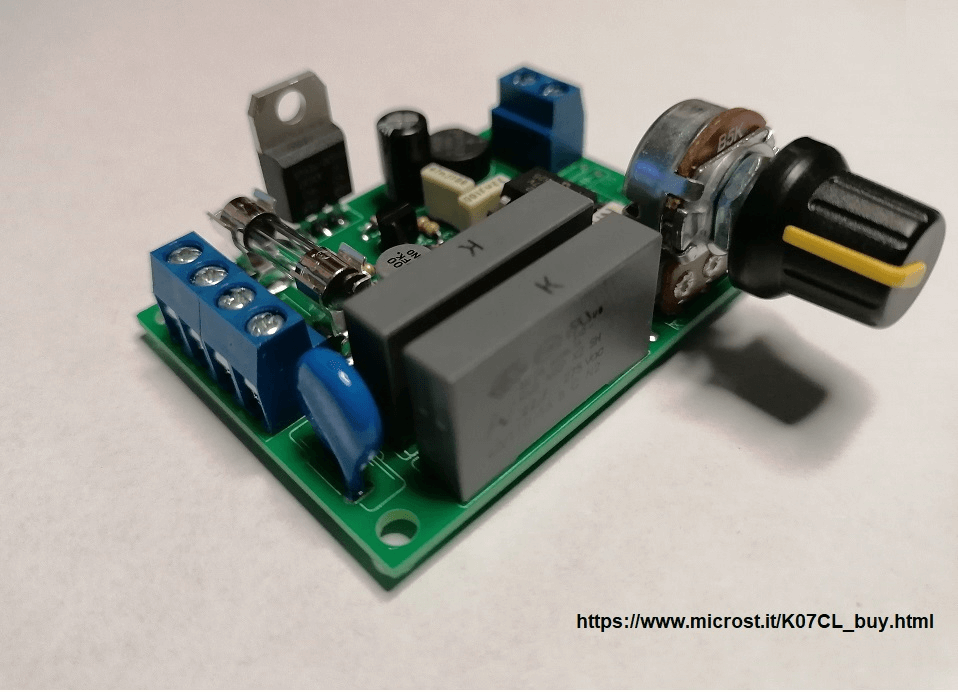

INTRODUCTION The MST_K07_CL is a regulator for universal motors (brushes) at 220V that allows to control the torque or to keep the rotation speed constant at the fixed value as the load varies. It is designed to work with washing machine motors equipped with a tachometer (or speed) sensor such as the MCA 30/64 motor. Figure 1 shows the photo of the controller assembled in the PCB version.

Fig. 1 - MST_K07_CL assembled DESCRIPTION OF THE REGULATOR The

MST_K07_CL regulator is the version with automatic torque control of

the MST_K07 universal motor regulator: the motor is adjusted so that

the rotation speed remains constant at the set value as the load

varies. If the load applied to the motor tends to reduce / increase the

rpm then the regulator will react by bringing the rpm value back to the

set one. This type of regulation is obtained through the closed loop

control that the regulator implements on the motor. This control is

based on the electrical signal coming from the speed sensor which

converts the rotation of the motor shaft into a proportional electrical

voltage. As a reference we take washing machine motors (such as the MCA

30/64) in which there is a tachometer sensor, coaxial to the motor,

which supplies an alternating voltage of amplitude proportional to the

rotation speed of the motor shaft. The MST_K07_CL regulator, suitable

for these types of motor, reads this voltage and compares it with a

voltage, set via a potentiometer, which represents the setting of the

rotation speed value to be adjusted. The regulator will then power the

motor so that the voltage value coming from the sensor, suitably

conditioned, remains equal to the voltage value set by the

potentiometer. To do this, the MST_K07_CL regulator uses an 8-bit

microcontroller, in which a firmware is loaded that implements a

digital PID regulator. The digital PID controllers then compare the

digital signals that represent the inputs (reference and feedback) and

generate an output signal which is the input of the power actuator.

Specifically, the actuator stage consists of the TRIAC piloted with the

ignition angle variation technique. In general, a TRIAC at the zero

crossing of the voltage present at its A1 and A2 anodes switches off

and on again when a current pulse is present on the GATE terminal. By

changing the instant of time in which the pulse is given on the GATE

terminal with respect to the previous zero crossing (it is said that

the phase angle is changed) the average voltage that powers the load is

varied as only a portion of the half-wave of voltage is supplied to the

load. So if you choose a zero ignition time (0 °) the whole half-wave

goes to the load and in this case you have the maximum power supply and

therefore the maximum motor speed. If you choose a time equal to half

of the half wave (90 °) only half of the sine wave will go to the load

and you have a 50% adjustment. Finally, if the TRIAC is turned on a few

moments before the next zero crossing (180 °), no voltage will go to

the load and there is a regulation of 0%. |

||

|

1 >>> |

||

|

|